Inovative Solutions Await You

Check our experts to your needs.

Technical support at every stage of your design process.

Have a product idea but need engineering expertise? We support you from concept to production-ready design — including manufacturability analysis, material selection, and performance optimization. With our guidance, you reduce risks and speed up your development timeline.

We digitize physical parts and bring them back to life.

Only have a physical sample? We recreate it using high-precision scanning and modeling, transforming it into a digital twin ready for reengineering or production. Reverse engineering lets us recover lost data, improve designs, and accelerate innovation.

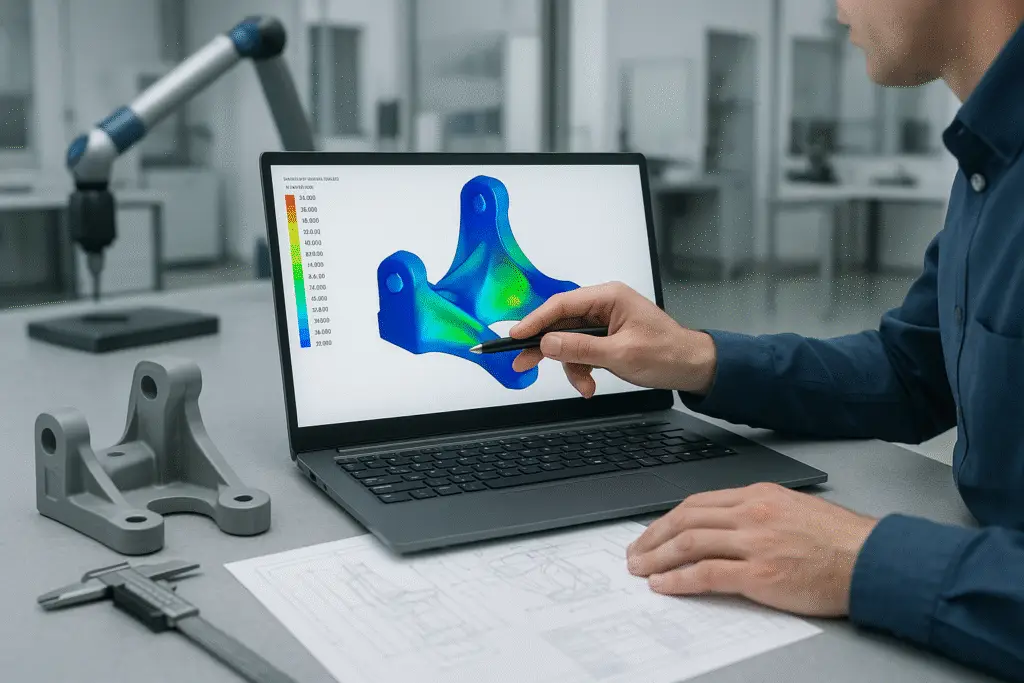

Analysis

Comprehensive engineering analysis is a key part of the development process at GMK3D. We offer detailed simulations, tolerance control, and structural validation to ensure your parts perform as expected under real-world conditions. Whether you’re working with plastic prototypes, metal components, or composite materials, our analysis services help you make informed design decisions and avoid costly revisions. From initial feasibility checks to finite element simulations (FEA), we support your product development journey with precision and reliability.

Turning ideas into testable physical parts.

A good prototype is key to smart decision-making. Using technologies like 3D printing, CNC machining, and silicone molding, we deliver high-quality prototypes tailored to function, durability, and appearance. Our rapid and flexible production helps you validate faster.

Your bridge between prototype and full-scale production.

Not ready for full-scale manufacturing? We’ve got you covered. Our low-volume and pre-series production services let you test your product in real-world conditions, attract investors, or prepare for launch. With flexible methods like RIM, vacuum casting, and soft tooling, we deliver scalable results — fast.

Project Management

Tailored project coordination — from concept to completion.

Product development isn’t just about an idea — it’s about managing time, budget, and technical details with precision. At GMK3D Engineering, we manage every stage of your project with a hands-on approach, ensuring smooth delivery and measurable success. For us, project management is not just a deadline — it’s the engine of innovation.

Stay Up to Date

Fill out the form to stay informed about developments and our new technological innovations.

Frequently Asked Questions

Common Questions About Our Services

What services do you provide?

We offer a complete range of services from engineering design to low-volume manufacturing.

Our expertise includes 3D scanning, reverse engineering, and prototype development.

Moreover, we support every stage from concept to production with modern technologies.

These include 3D printing, CNC machining, silicone molding, vacuum casting, and RIM.

As a result, we help you turn ideas into high-quality functional parts — fast and efficiently.

What industries do you serve with your low-volume production services?

We mainly serve the automotive, medical, and defense industries.

However, our flexible manufacturing methods also support startups and R&D teams.

In addition, product designers from various sectors benefit from our rapid prototyping services.

Can I get support even if I only have an idea or sketch, not a 3D model?

Yes, absolutely. We support projects at any stage, including early ideas and hand sketches.

Whether you have a sample or just a concept, our engineers can develop the 3D model.

Then, we move your project into production using the best-suited manufacturing method.

Do you offer reverse engineering for broken or legacy parts?

Yes, we do. Our team specializes in reverse engineering using high-precision 3D scanning.

For instance, we can recreate parts without CAD data — even if they’re broken or outdated.

As a result, we deliver production-ready 3D files for accurate reproduction or improvement.