Design & Development and Reverse Engineering

Precision Engineering for Real World

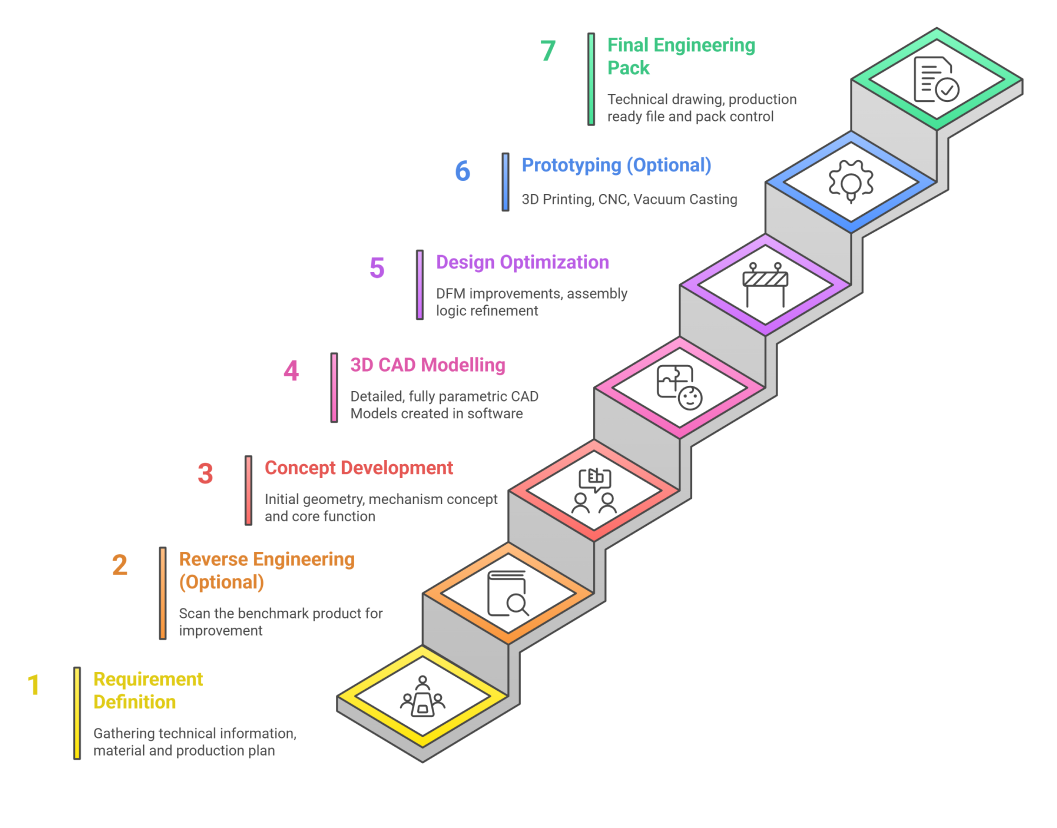

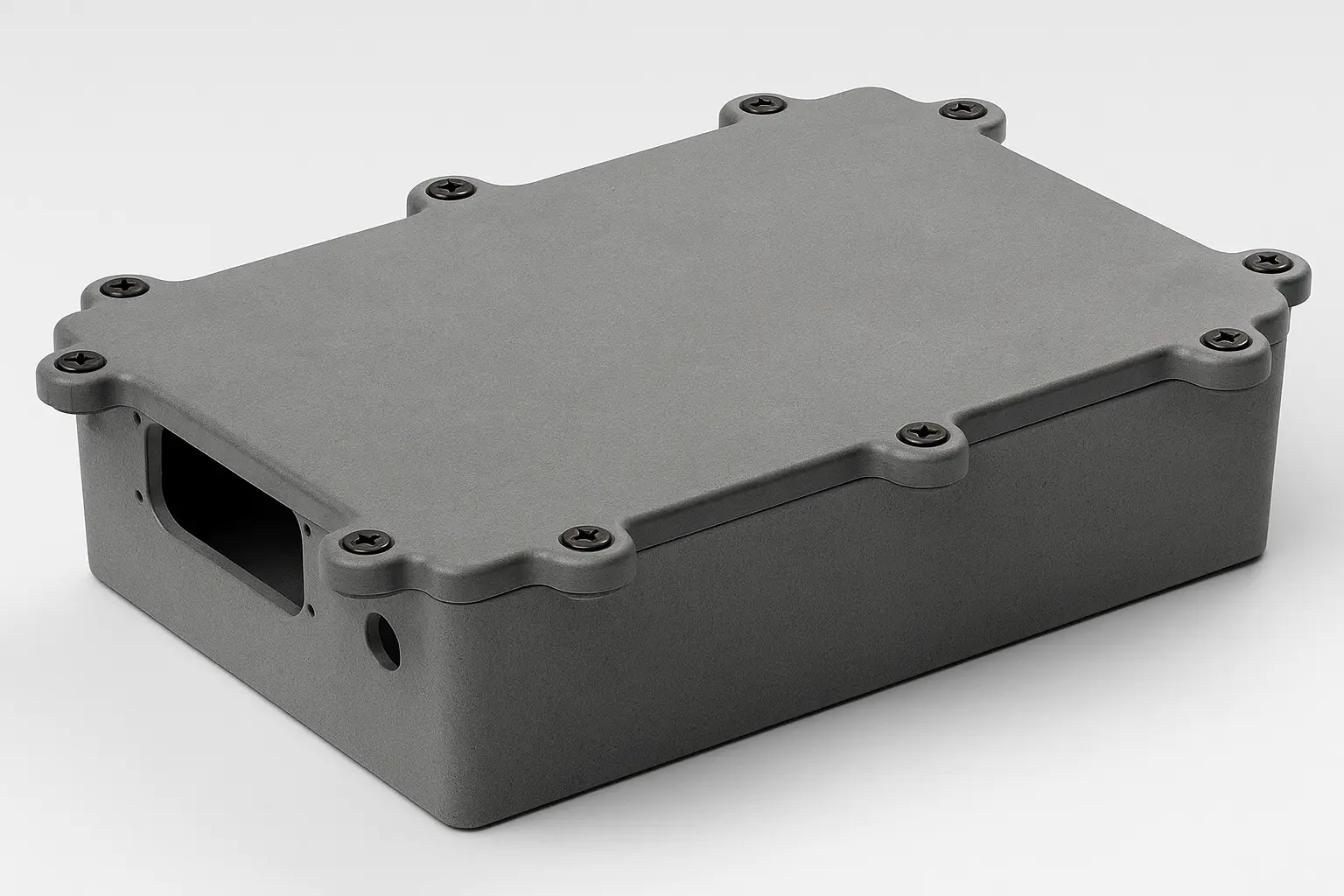

At GMK3D, we specialize in the design and development of plastic parts, functional mechanical components, and production-ready fixtures. Our engineering-driven approach ensures every part is optimized for manufacturability, durability, and performance — whether it will be injection molded, 3D printed, CNC machined, or silicone molded.

We work closely with manufacturers, R&D teams and product owners to turn requirements into precise, reliable, and production-ready designs.

What We Offer?

We are happy to meet you!

We design functional and manufacturable parts tailored to your requirements.

Our expertise covers plastic components, mechanical mechanisms, assemblies, and precision-engineered elements.

Every design is optimized for durability, performance, and production feasibility, ensuring smooth transition into manufacturing.

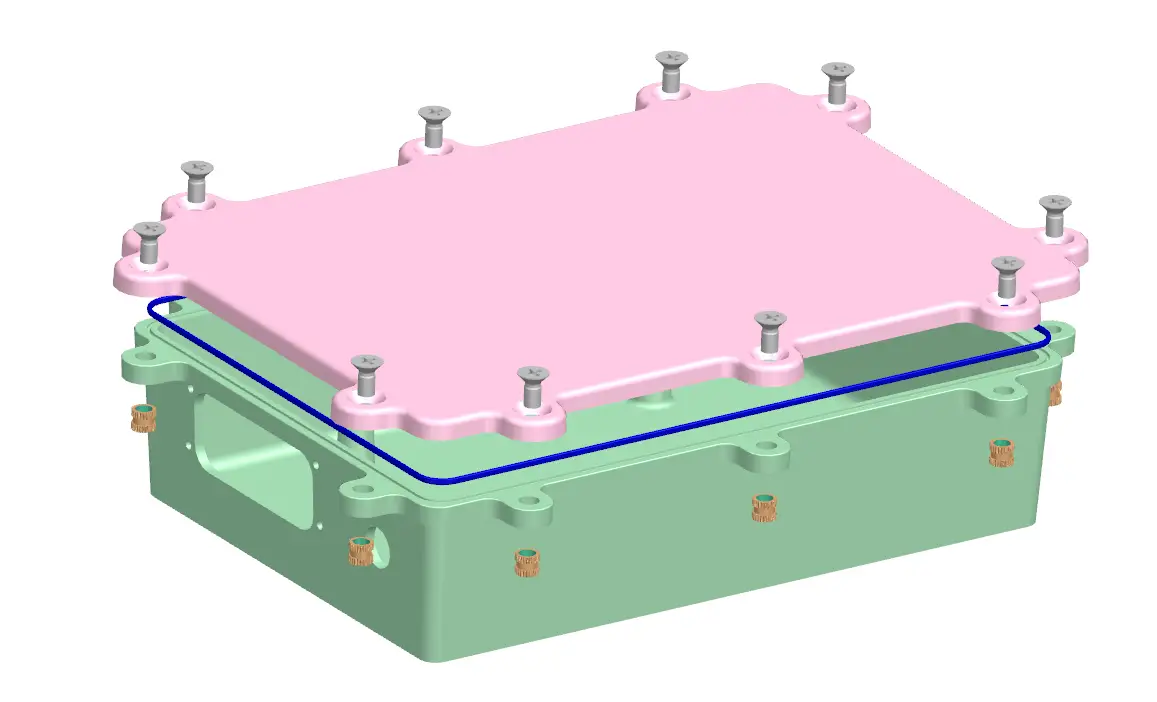

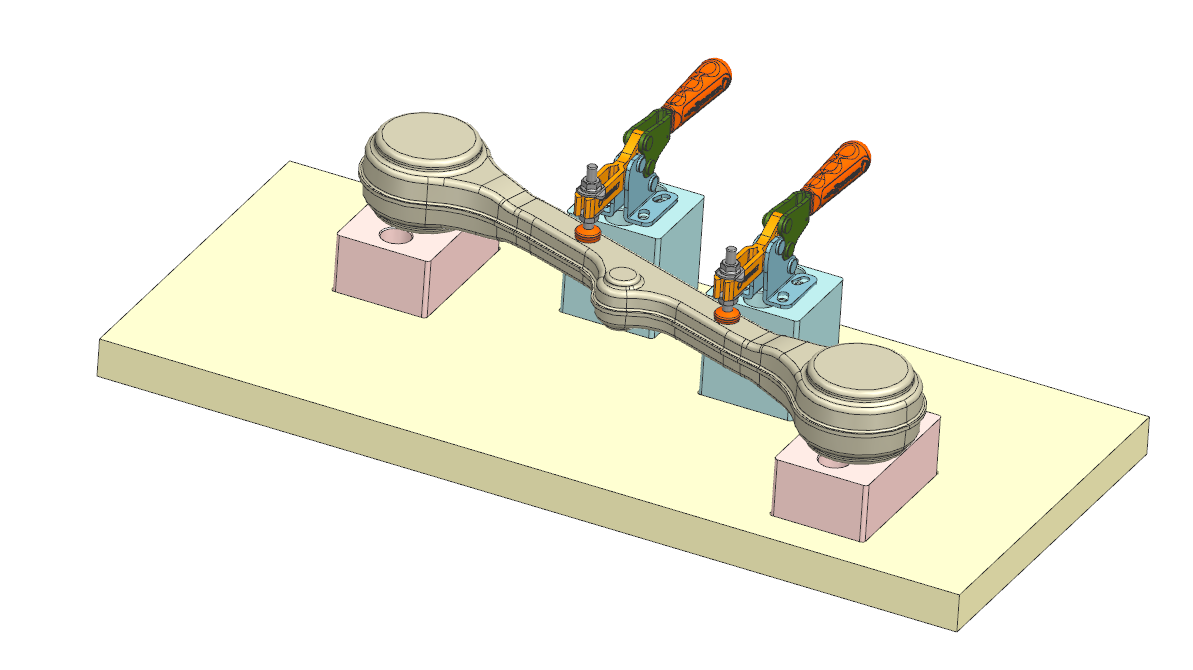

We engineer custom tooling, jigs, and fixtures to improve production accuracy, repeatability, and efficiency.

Our designs support CNC machining, assembly lines, measurement setups, and quality control processes—offering reliable solutions for both prototyping and mass production environments.

We recreate accurate digital models of existing components using structured measurement, 3D scanning, and engineering reconstruction techniques.

Our process enhances old or undocumented parts, improves manufacturability, and allows seamless integration into new or updated systems.