3D printing, also known as additive manufacturing, is a production method where parts are built layer by layer directly from a digital 3D model. This technology enables the fast and cost-effective production of complex geometries that are difficult or impossible to manufacture using traditional methods.

3D printing is widely used for functional prototyping, design validation, tooling support, and low-volume production. It allows engineers and manufacturers to reduce development time, lower costs, and iterate designs quickly before committing to mass production.

At GMK3D Engineering, we offer multiple industrial 3D printing technologies to match different mechanical, visual, and functional requirements.

What is the "3D Printing"?

OUR 3D PRINTING TECHNOLOGIES

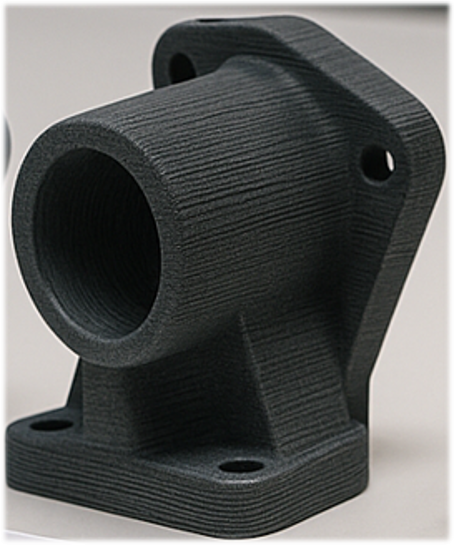

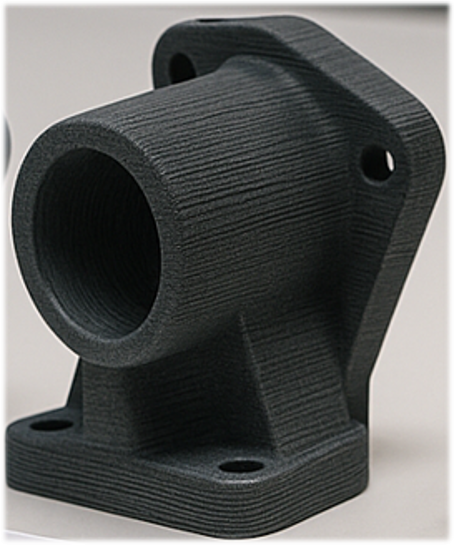

FDM builds parts by extruding thermoplastic filaments layer by layer.

Cost-effective solution

Wide material selection

Fast turnaround

Concept models

Early-stage prototypes

Assembly and fit tests

Fixtures and jigs

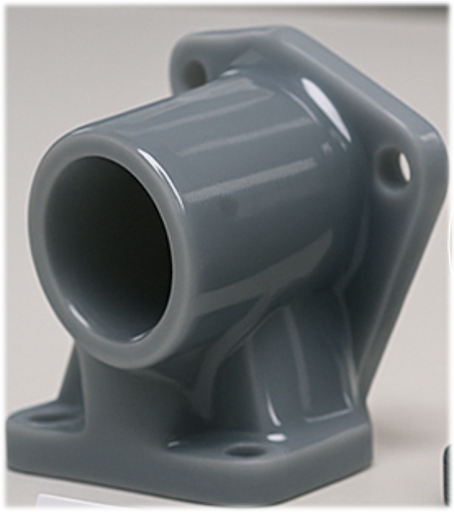

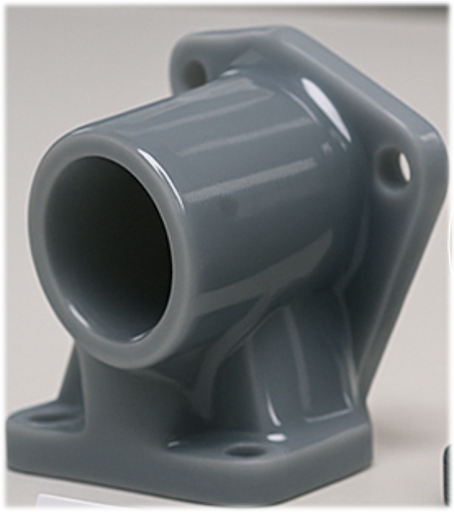

SLA uses a UV laser to cure liquid resin into highly detailed and smooth parts.

Excellent surface finish

High dimensional accuracy

Fine details and sharp edges

Visual and presentation models

Design verification

Master patterns for silicone molds

Medical and consumer product prototypes

SLS and MJF are advanced powder-based technology that produces strong, functional plastic parts with uniform mechanical properties.

High strength and durability

Excellent dimensional consistency

Suitable for end-use parts

No support structures required

Functional prototypes

Low-volume production parts

Snap-fit components

Housings, enclosures and mechanical parts

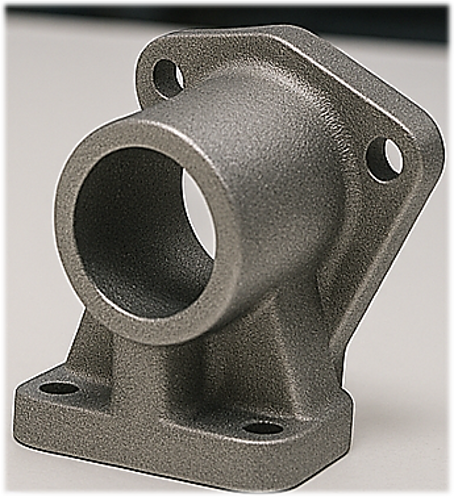

SLM is a metal 3D printing technology that fully melts metal powder using a high-power laser to produce dense, high-strength parts.

Fully dense metal parts

High mechanical strength

Complex internal channels and geometries

Functional metal components

Lightweight structural parts

Industrial and engineering applications