VACUUM CASTING & RIM CASTING

Combined with our design, vacuum casting, and RIM casting capabilities, we provide a seamless transition from prototype to production.

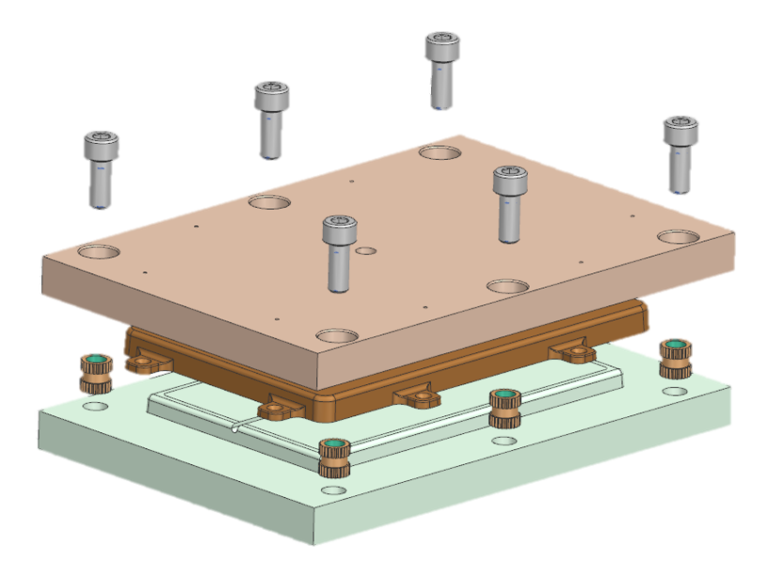

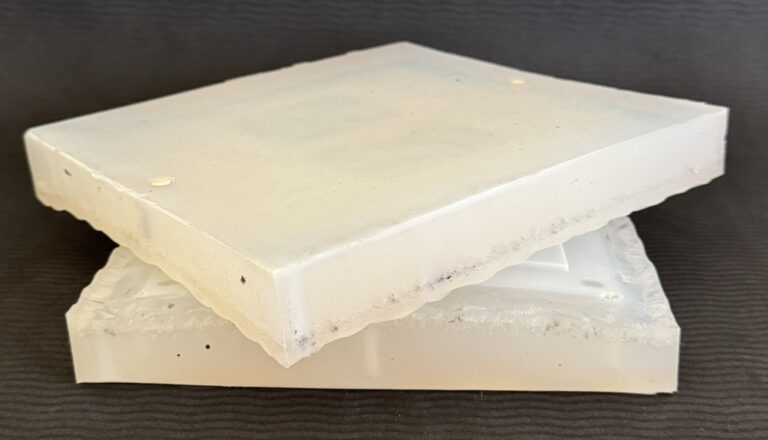

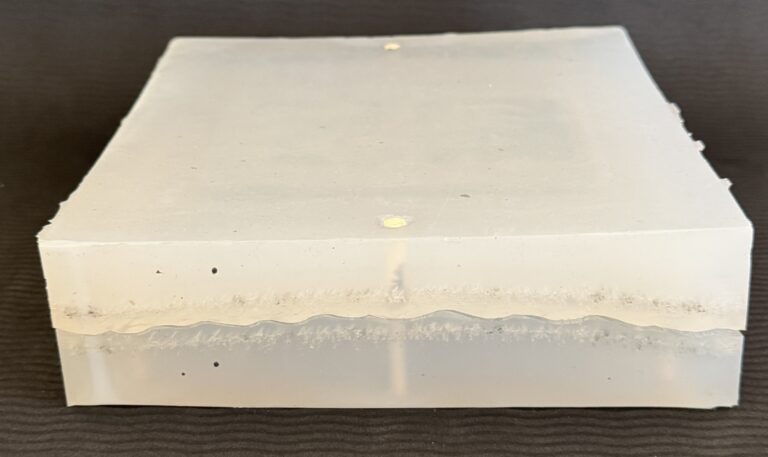

Vacuum Casting is a manufacturing process used to produce high-quality prototypes and low-volume parts by casting polyurethane resins into silicone molds. The method uses a vacuum chamber to remove air bubbles and ensure that the final part has excellent surface quality, accurate dimensions, and strong mechanical performance. Because the process is fast, cost-effective, and capable of replicating complex geometries, it is widely preferred for functional prototypes, product testing, and small batch production.

Vacuum Casting is ideal for applications where injection-molded part quality is required but production volumes do not justify expensive steel molds. The technique also enables the use of a wide variety of materials—rigid, flexible, transparent, heat-resistant, or rubber-like—making it a versatile solution for industries such as consumer electronics, automotive, medical devices, and industrial equipment.

What is the "Vacuum Casting"?

VACUUM CASTING APPLICATION AREAS

We are manufacturing, Housings and covers Anatomical models Large panels, bumpers Fair models Transparent parts Rubber materials Functional parts needs Field test samples Necessary products for market research Low volume end user parts needs

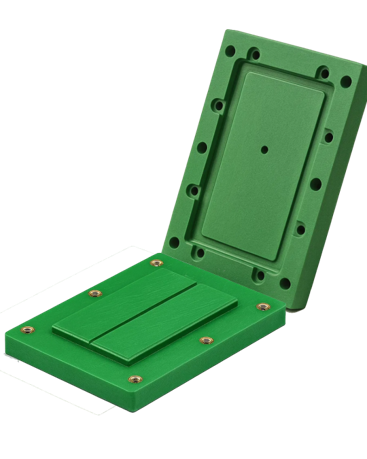

RIM Casting (Reaction Injection Moulding) is a low-pressure molding process used to manufacture large, thick-walled, and structurally strong plastic parts. The process involves mixing two or more liquid reactive materials—typically polyurethane or epoxy—and injecting them into a closed mold, where they chemically react and cure to form the final part.

Unlike traditional injection molding, RIM Casting operates at low injection pressures and uses lower-cost molds, making it an efficient and economical solution for low to medium production volumes. The process allows for complex geometries, integrated ribs, thick sections, and high structural rigidity while maintaining excellent surface quality.

RIM Casting is commonly used for producing functional housings, enclosures, panels, covers, and structural components where strength, dimensional stability, and design freedom are critical. It is widely applied in industries such as automotive, industrial equipment, agriculture, transportation, and construction.

What is the "RIM (Reacted Injection Moulding) Casting"?