Engineering Projects & Case Studies

Explore how GMK3D turns innovative ideas into precise, production-ready solutions across various industries.

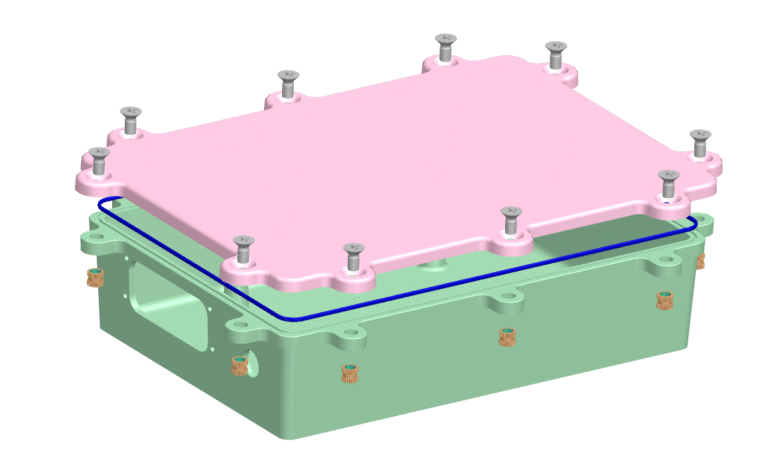

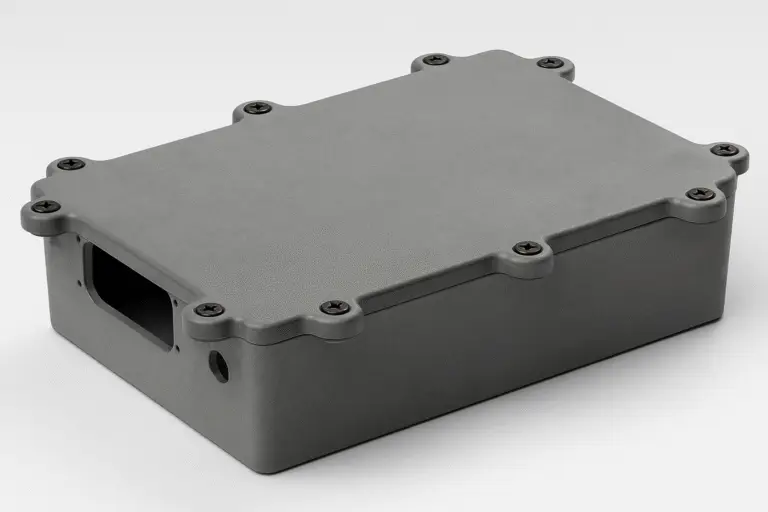

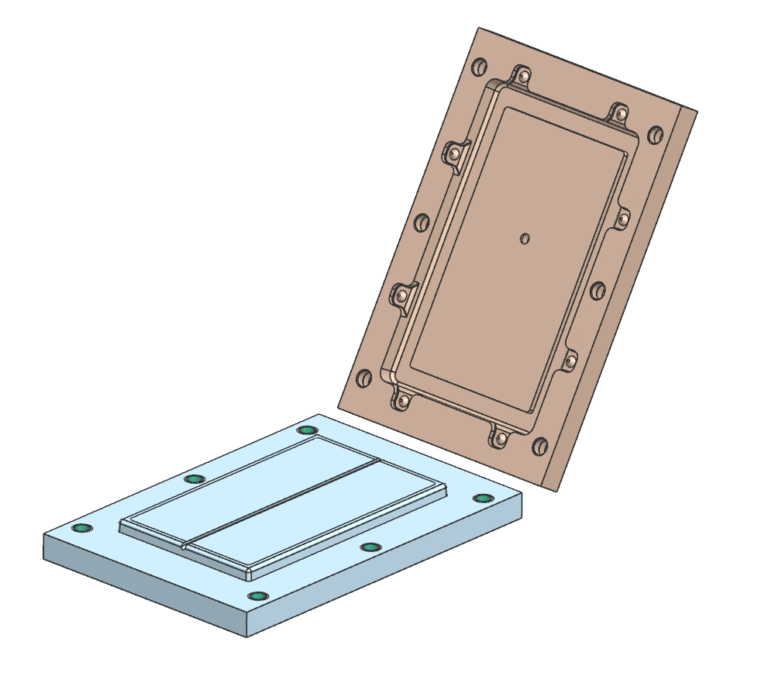

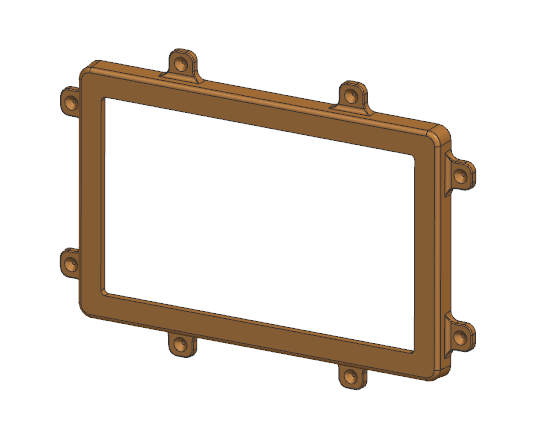

ECU BOX with IP67 Sealing feature. Suitable for outdoor working conditions.

- Max working temp.:130°C

- Hardness: Shore D1 87

- Flexural Module: 2300 Mpa

- Max. Flexural Strength: 80 Mpa

- Tensile Strength: 60 MPa

- Hardness: Shore 40A

- Max working temp.:-40°C/90°C

- Tensile Strength: 2.70 Mpa

- Tear Resistance: 11,5kN/m

.

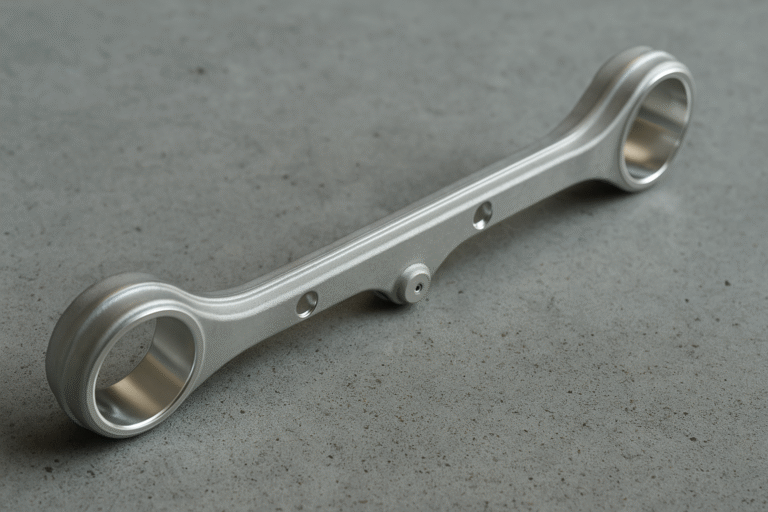

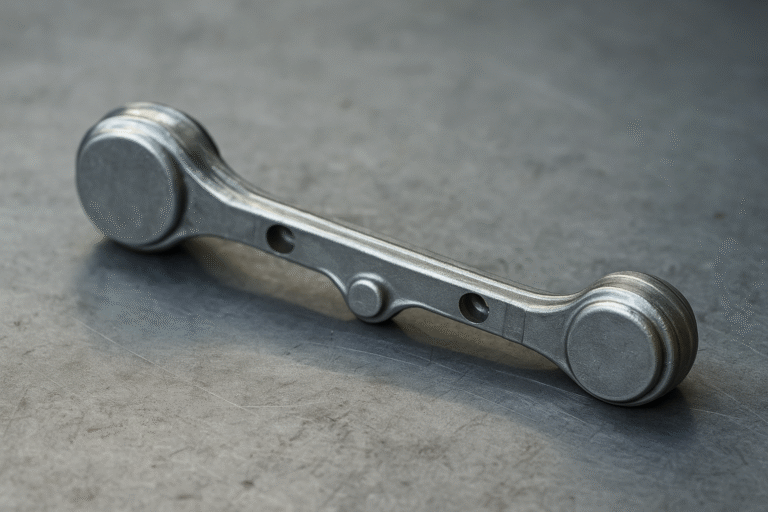

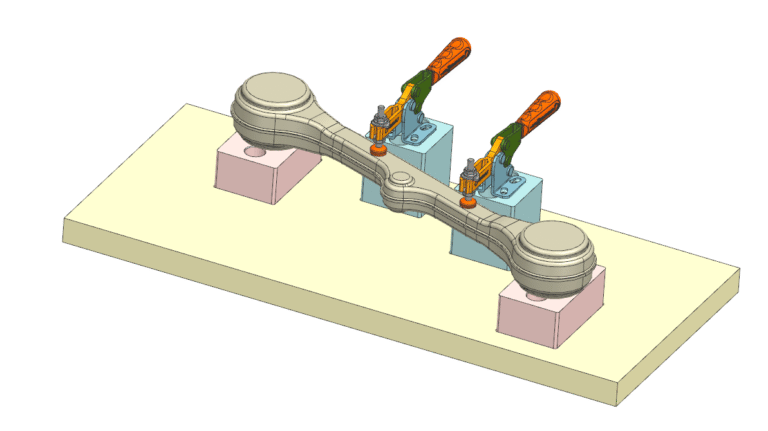

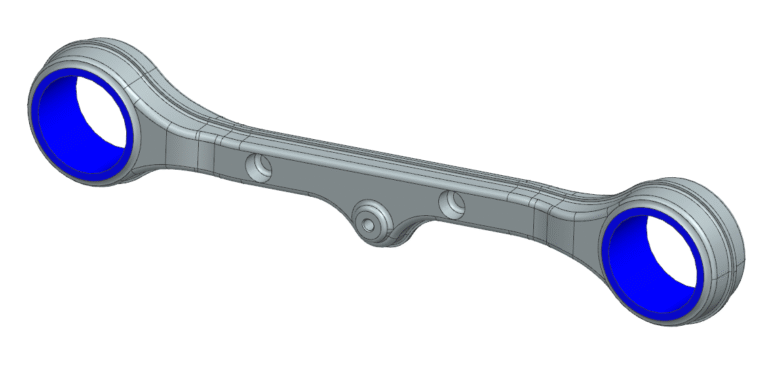

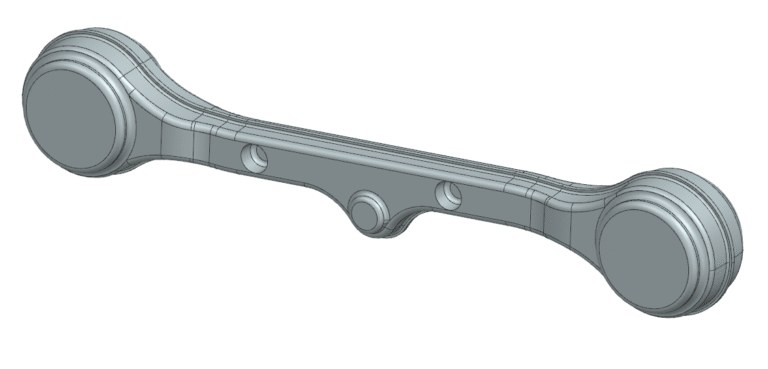

We design, optimize, and manufacture aluminum forged suspension arms, combining topology analysis, fixture design, and precision machining for superior performance.

- Link Design

- Machining Fixture Design

- Topology Analysis (for Future)

Low Volume Aluminium Forging

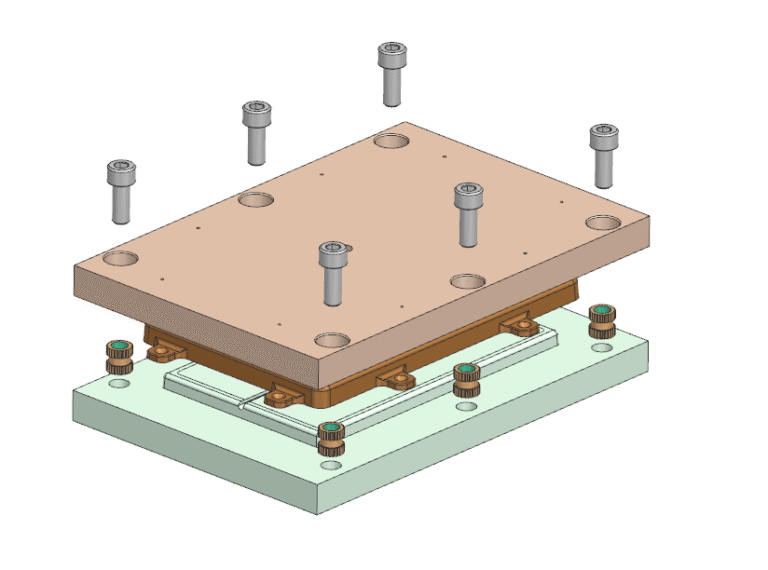

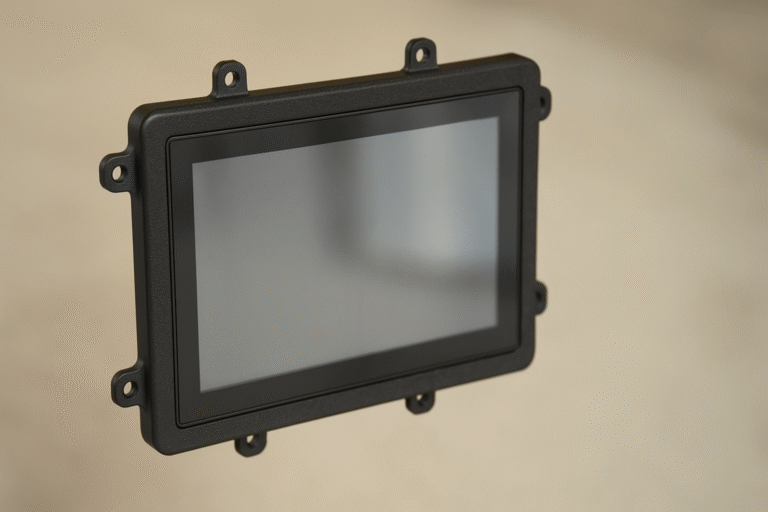

We produce plastic components using manufacturing methods selected for optimal efficiency based on part complexity and volume. The Screen Cover project, realized through RIM technology, reflects our precision-driven approach to low-volume plastic production.

- Product Design

- RIM Tooling Design

- Product Manufacturing

Low Volume Reacted Injection Moulding